DCPower Batteries & Foodstuffs North Island

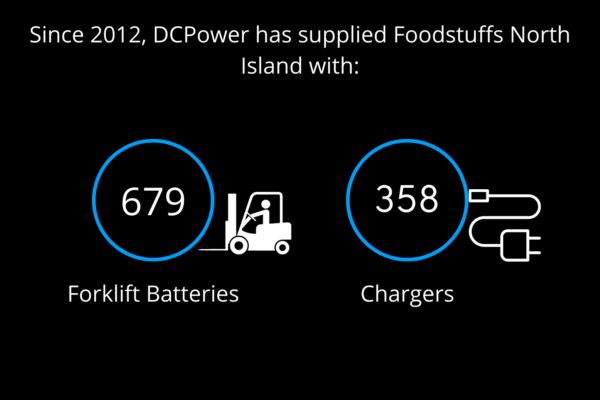

DCPower and grocery giant Foodstuffs North Island have endured a long-standing relationship since 2005. Offering unrivalled battery knowledge and expertise that has undoubtedly contributed to smooth operations and significant environmental gains for Foodstuffs cutting-edge distribution centers around the North Island.

The relationship has ensured the ongoing success of Foodstuffs, as the needs of their business have grown over time from a single shift to a now 24/7 (3-shift) operation. This has resulted in increasing pressure on the company’s materials handling equipment. We were challenged with balancing the needs of the business with an acceptable return on investment: Minimizing downtime whilst still achieving an acceptable performance from the Foodstuffs forklift battery fleet which can hold an average value of $8,000 each.

Success with Gel

The 4-year trial was so successful that most of the gel batteries involved far exceeded their predicted service life of 3 years, with several still in operation today!

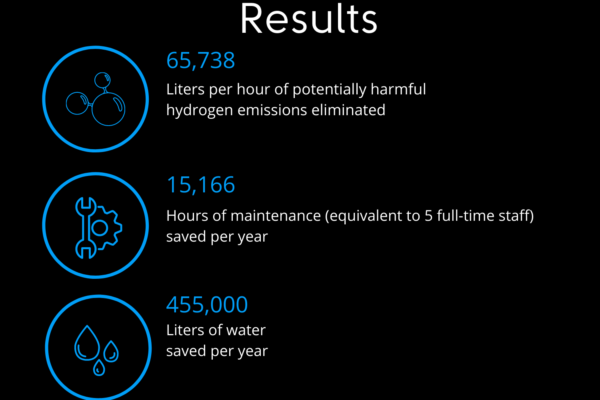

Data collected during the period proved that switching five hundred 24V batteries from flooded to gel technology saves 455,000 liters of water and 15,166 hours of maintenance – the equivalent of 5 full-time staff – per year. In addition, the switch completely eliminates the 65,738 liters per hour of the potentially harmful hydrogen emissions that a flooded battery fleet generate!

Fast Forward to 2021

and the operational needs of Foodstuffs have changed again, with most sites (including the new Landing Drive Distribution Centre) primarily running a 24/7, 3-shift operation. The downside is that there is very little charging time available on any given day. Such operation is not well suited to any lead-acid technology; so we are at it again with another trial – this time using lithium-ion LiFePO4 (lithium iron phosphate) batteries which offer extended longevity and superior safety. Whilst still comparatively new to the market, lithium offers many of the same benefits as lead-acid gel but with the added advantage of the ability to recharge in less than 110 minutes per day.

15 Years ago

Foodstuffs were operating with traditional flooded lead-acid batteries. Whilst great for the environment – they are 99% recyclable – flooded batteries require intensive maintenance and adequate charging time (a minimum of 8 out of every 24 hours). Back then, it was not uncommon to purchase two batteries per machine. This also necessitated a ventilated battery room, access to filtered water and, in most cases, costly battery-changing equipment.

In 2010

with Foodstuffs operating on a 2-shift basis, we pioneered a trial at Foodstuffs Roberts Line Distribution Center using new lead-acid technology – in which the internal electrolyte is a gel substance, rather than liquid. The purpose of the trial was to find a solution that fulfilled Foodstuffs’ evolving operational requirements whilst simultaneously providing environmental and financial gains to the business.

Safe disposal methods

for lithium are still in development, however the manufacturer of the trial lithium batteries (Systems Sunlight) is offering a disposal scheme whereby used lithium forklift batteries can be returned for recycling, refurbishment or for retirement (where they can be refurbished and used again in much gentler standby applications).

QPlug Innovation

We have not only championed the introduction of this new technology, our open minds and innovative approach have also seen other developments come to light. In 2015, based on feedback from Foodstuffs, we developed a unique plugging mechanism designed to incorporate two charging steps into one. The QPlug was designed and built in-house and included some battery modifications that were made at factory level. It is in use with all Foodstuffs gel batteries today.

Adopting the QPlug reduced downtime and the incidence of damage, and virtually eliminated the potential for human error.